VALUE ADDED OPTIONS _ OPTICAL BONDING - NOBR Series

Optical Bonding of LCM Module with glass

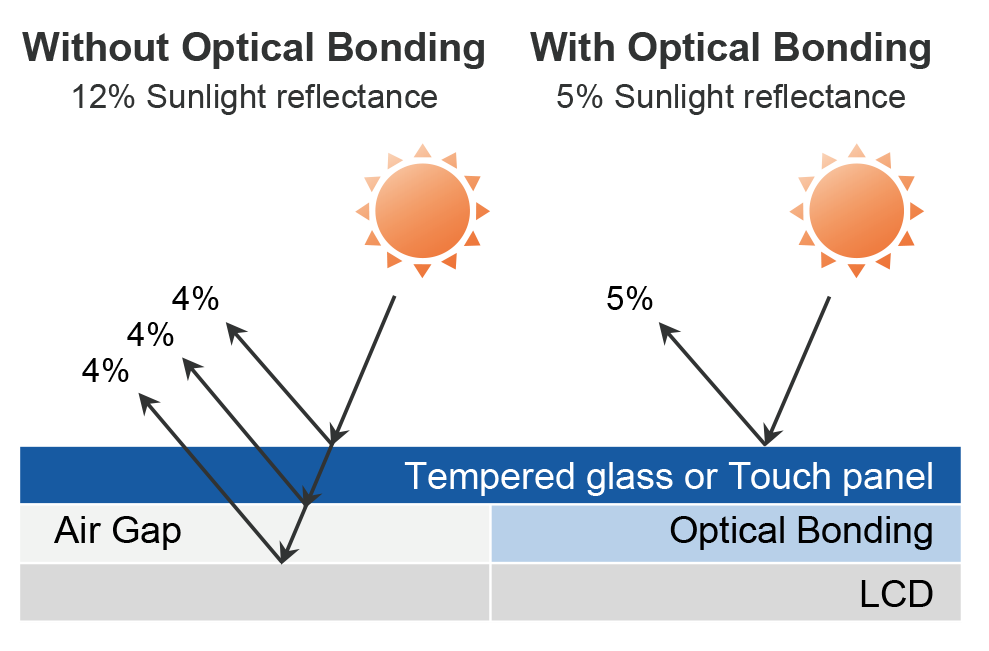

- Optically clear resin between LCD module and cover glass

- High image quality and sharper contrast

- For Military, Medical, Transportation, Outdoor Display

Inserting Optically Clear Resin between LCD Module and the cover glass, touchscreen improves luminance, shock resistance and performance of display.

Advantages

- High image quality and sharper contrast

- Readability by eliminating reflections

- Reduced parallax

- Resistance to external influences

- Condensation prevention

- Long-term reliability

- Re-bond ability, reversible for repair

Applications

- Military, Medical rugged displays

- Transportation: Marine, In-flight, In-vehicle

- EMI / REI (ITO, mesh, etc.) filters

- Touch screens

- Outdoor information displays and Kiosks

- Vending machines

| ENVIRONMENTAL PERFORMANCE | |

|---|---|

| Temperature | Stable under multiple ESS cycles between -40°C ~ +95°C |

| Humidity | 95% (R.H. at 70 °C for a minimum of 50 hours) |

| U / V solar exposure | Stable fill adhecive & sealing gasket under simulated UV / solar exposure |

| Chemical resistance | Stable in contact with most sillicone, polyurethane and polysulfide adhesive sealants. *Contact with Solvent Systems (methyl ethyl ketone, acetone, toluene or similar materials) will cause damage. |

| THERMAL HARDENING ADHESIVE – CURED BY HEAT CONDITION | |

|---|---|

| Material type | 2 – part transparent silicone gel |

| Mixing ratio | 1 : 1 |

| Viscosity | 1,980 mPa.s |

| Cure temperature | 65°C |

| Cure time | 46 min |

| Transmittance | > 99.0 % – UV-VIS |

| Haze | 0.1 |

* The specification is subject to change without prior notice.